The Essential Role of a Plastic Mold Maker in Modern Manufacturing

In the ever-evolving landscape of manufacturing, the role of a plastic mold maker has become increasingly vital. As industries strive for efficiency, precision, and sustainability, the plastic injection mould manufacturer stands at the forefront, crafting the tools that shape our daily lives. This article delves deep into the world of plastic mold making, exploring its significance, the manufacturing process, modern innovations, and choosing the right manufacturer for your needs.

Understanding Plastic Mold Making

Plastic mold making involves creating a hollowed-out block, known as a mold, in which liquid plastic is injected to form various products. This intricate process is pivotal for numerous industries, including automotive, consumer goods, medical, and electronics. Mold makers are crucial in designing and producing molds that cater to specific product requirements, ensuring that every item produced meets rigorous quality standards.

The Process of Plastic Injection Molding

The journey from concept to final product in plastic injection molding entails several key steps:

- Design: The process begins with a detailed design of the product. Engineers use CAD (Computer-Aided Design) software to create 3D models, determining dimensions, weight, and performance metrics.

- Mold Construction: Once the design is finalized, mold makers create the physical molds. This involves CNC machining and other precision fabrication techniques, ensuring that the molds meet tight tolerances.

- Molding Process: Liquid plastic is heated until it becomes viscous and is then injected into the mold under high pressure. After cooling, the mold is opened, and the final product is ejected.

- Finishing: Depending on the application, additional processes like trimming, surface finishing, and painting may be required to complete the product.

Why Choose a Professional Plastic Mold Maker?

Opting for a qualified plastic mold maker is essential for ensuring high-quality outcomes. Here are several reasons why professionalism matters:

- Expertise: Skilled mold makers possess extensive knowledge in materials, design principles, and manufacturing processes, leading to superior product quality.

- Customization: A professional can tailor molds to specific product requirements, allowing for innovation and differentiation in the marketplace.

- Cost Efficiency: Investing in quality molds can reduce production costs in the long run by minimizing defects and improving production speeds.

- Reputation: Choosing a reputable plastic injection mould manufacturer ensures reliability and customer satisfaction, critical for business success.

Key Trends in Plastic Mold Making

The field of plastic mold making is witnessing several transformative trends that can enhance productivity and innovation:

1. Automation and Robotics

The integration of automation in the molding process is streamlining operations, reducing human error, and increasing efficiency. Robotics can handle repetitive tasks, allowing skilled workers to focus on more complex challenges, driving innovation in product design and quality control.

2. Sustainable Practices

With growing environmental concerns, sustainability has become paramount in manufacturing practices. Modern mold makers are adopting eco-friendly materials and processes to minimize waste and energy consumption. This shift not only benefits the environment but also meets the increasing consumer demand for sustainable products.

3. Advanced Materials

The world of plastics is evolving, with new and advanced materials being introduced regularly. These materials offer improved strength, flexibility, and heat resistance, allowing manufacturers to create more durable and innovative products. Understanding how to work with these materials is essential for plastic mold makers.

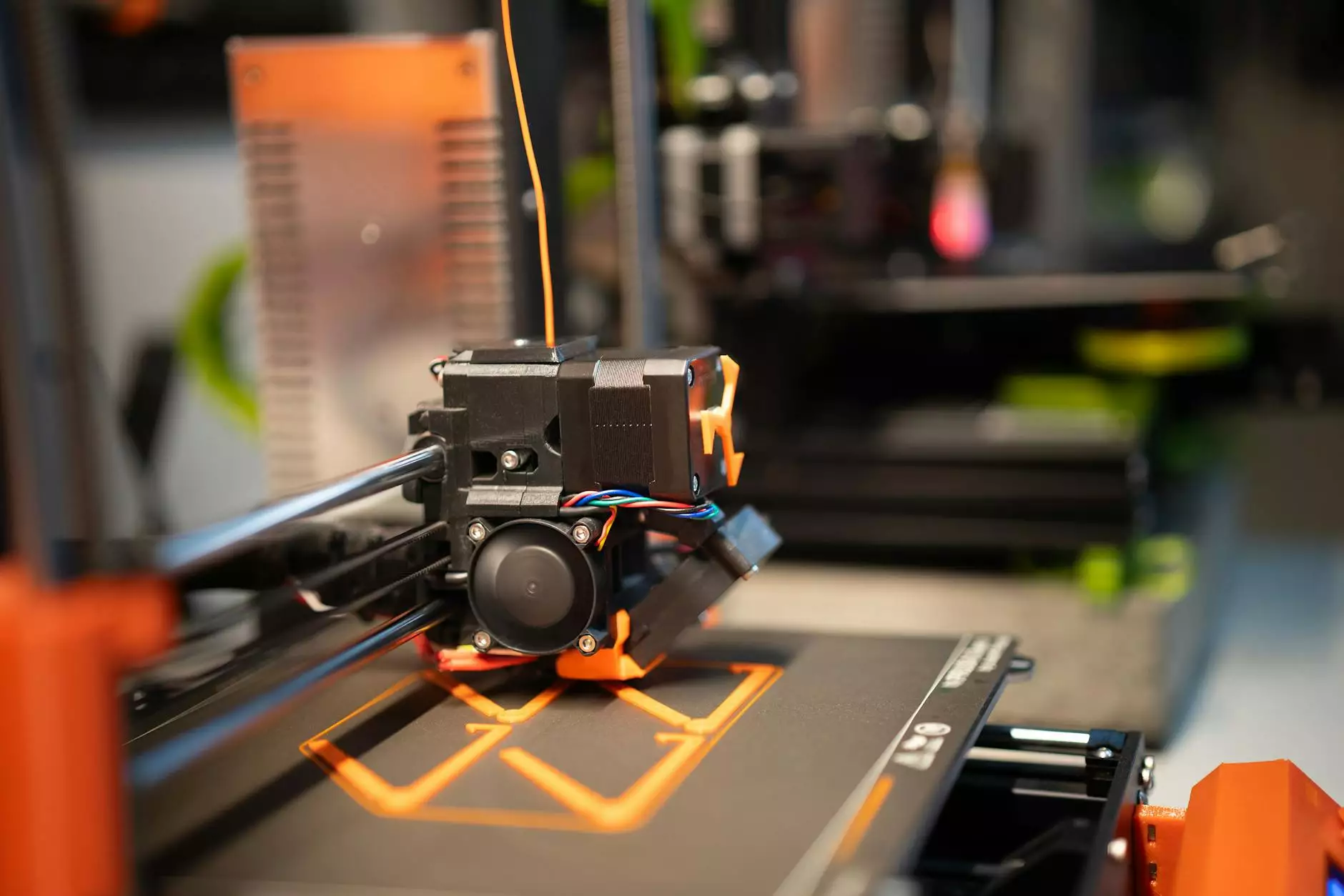

4. 3D Printing Technology

3D printing is reshaping how molds are designed and produced. It allows for rapid prototyping, enabling mold makers to create and test molds quickly. This advancement leads to faster production cycles and reduces the time-to-market for new products.

Choosing the Right Plastic Injection Mould Manufacturer

1. Experience and Expertise

Look for a manufacturer with a proven track record in the industry. Experience often correlates with the ability to troubleshoot issues effectively and innovate solutions tailored to specific client needs.

2. Technology and Equipment

Evaluate the technology and machinery used by the manufacturer. The latest equipment typically means higher precision and efficiency in mold production, leading to better end products.

3. Quality Assurance Processes

A reputable manufacturer should have robust quality assurance practices in place, including regular inspections and testing of molds to ensure they meet industry standards.

4. Customer Support

Strong customer support is vital. Ensure that the manufacturer provides comprehensive support during the design, production, and after-sales phases to address any concerns quickly.

5. Cost Transparency

Understand the cost structure and ensure there are no hidden charges. Receiving a clear and detailed quote upfront helps in budgeting and planning.

The Future of Plastic Mold Making

The future of the plastic mold making industry is promising, driven by technological advancements and increasing demand for tailored solutions. As industries continue to evolve, the role of the plastic mold maker will expand, incorporating more innovative practices and sustainable approaches.

1. Customization and Flexibility

As market demands shift, manufacturers that can offer customized molds at competitive prices will lead the industry. Flexibility in production will be a key component in meeting diverse customer needs.

2. Integration with Digital Technologies

The rise of Industry 4.0 and the Internet of Things (IoT) are creating opportunities for mold makers to integrate digital solutions into their processes, enhancing efficiency and connectivity.

3. Focus on Education and Training

As the industry progresses, continuous training for mold makers will be crucial. Staying updated with latest trends, materials, and technologies will ensure that manufacturers can meet the evolving demands of the market.

Conclusion: The Indispensable Plastic Mold Maker

In conclusion, the role of the plastic mold maker is indispensable in today’s manufacturing landscape. With their expertise, attention to detail, and commitment to quality, mold makers are essential partners in creating the products that shape our world. As you consider your next project, partnering with a highly skilled plastic injection mould manufacturer ensures that you will achieve the highest standards of excellence and innovation. Invest in your future by choosing wisely and understanding the profound impact a plastic mold maker can have on your product's success.